Collaborative Robots

Collaborative Industrial Robots for Precise Automation

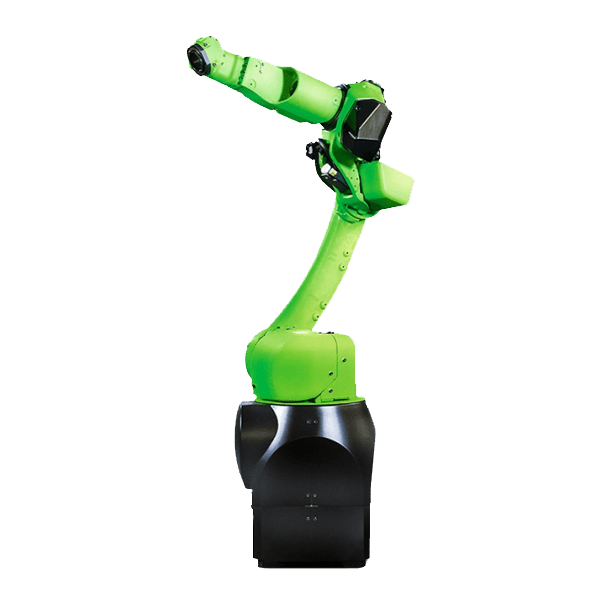

6-Axis Collaborative Robots for Industrial Automation

Robotic Automation Systems offers 6-Axis collaborative industrial FANUC robot automation needs. Collaborative robots are meant to operate safely side-by-side with human operators, as well as other machinery, cobots, and robots. This combination can be much more productive than using human operators or industrial robots alone. Call our team today to learn more!

Collaborative Robots

Collaborative robots, or cobots, are industrial robots that are capable of learning numerous tasks to assist human beings in production. Some of the key benefits of our collaborative robots include:

- Ability to be mobile multi-taskers

- Small and lightweight

- Easy to operate and switch between tasks

- Many models can be programmed for new operations

There are several types of collaborative robots available to suit a broad range of production and manufacturing needs. Most collaborative robots can be integrated into production systems with tools like welding tips, vision cameras, suction cup grippers, and more.

Collaborative Robot Applications

Collaborative robots are commonly used for:

- Pick and place

- Machine tending

- Packaging and palletizing

- Process tasks, when equipped with end effector tools

- Finishing (sand, polish, deburr, trim)

- Quality inspection, when equipped with a vision camera

- Assembly

- Dispensing

- Painting, coating, dipping

Contact Robotic Automation Systems Today

The advantages of using collaborative robots are becoming more widely known among several different manufacturing and production industries. At Robotic Automation Systems, we specialize in employing top-of-the-line collaborative robots from leading industrial robot manufacturers throughout the United States.

Discover more about Robotic Automation Systems and what our clients have to say about our expertise, high level of customer service, and integrated solutions. Contact us to learn more about our collaborative robots!