Photo Gallery

Custom End of Arm Tooling (EOAT) Solutions

Robotic Automation Systems is a leader and innovator of custom-designed, robustly engineered, and constructed end of arm tooling (EOAT), grippers, and end effectors, for a wide range of robotic automation applications in horizontal and vertical plastic injection molding automation, including insert molding automation and in-mold decorating automation.

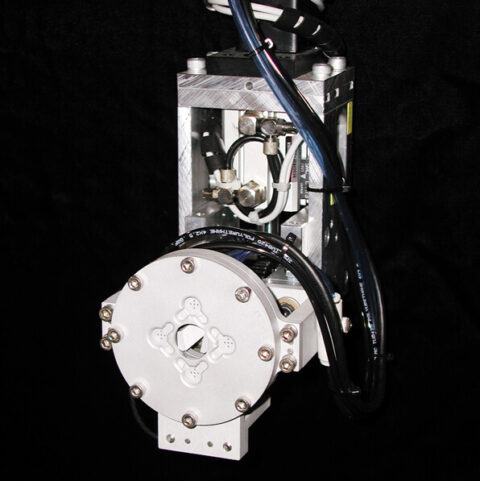

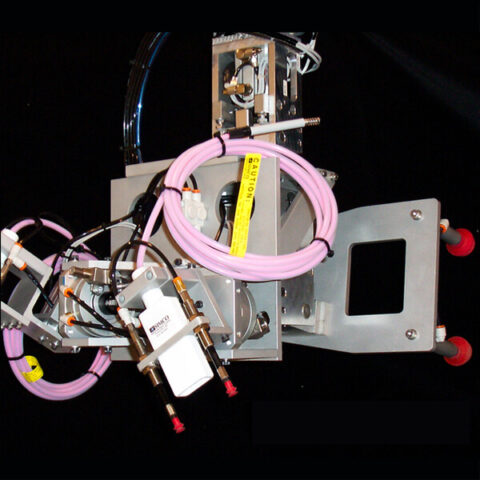

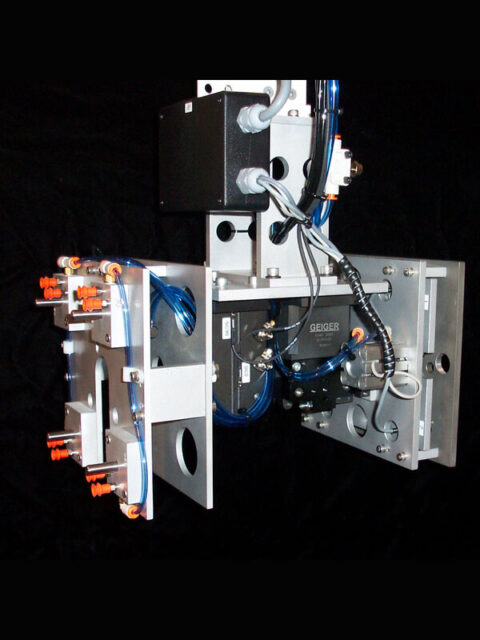

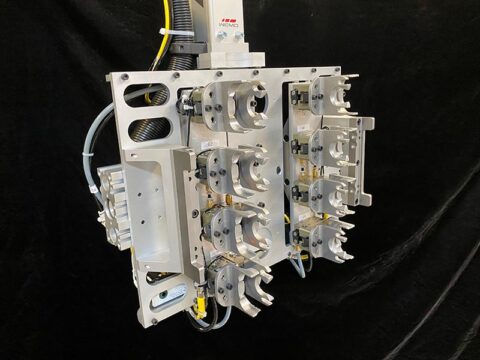

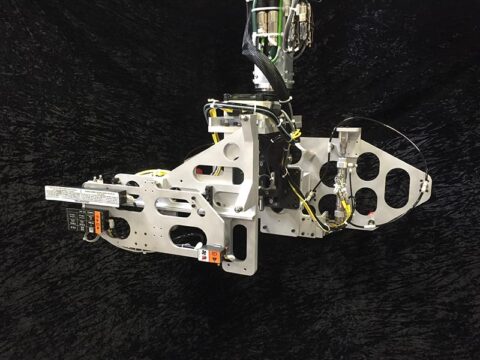

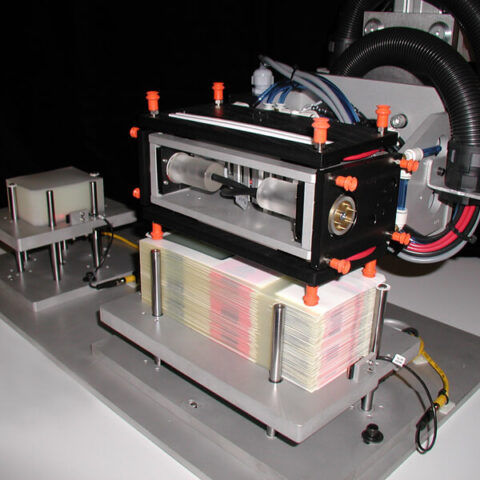

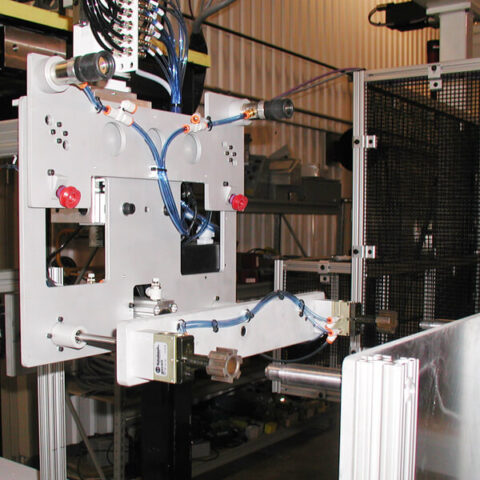

Custom end of arm tool for automated retrieval of small caps using a vacuum system without suction cups

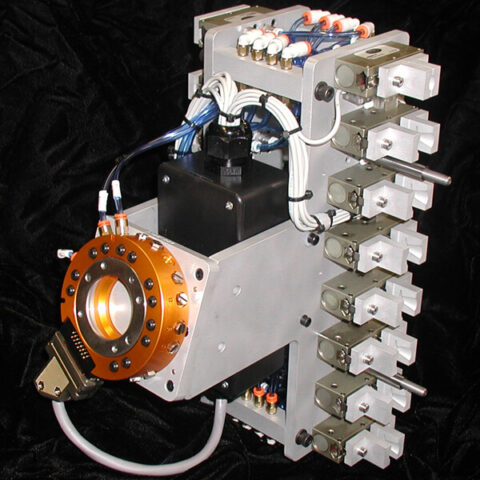

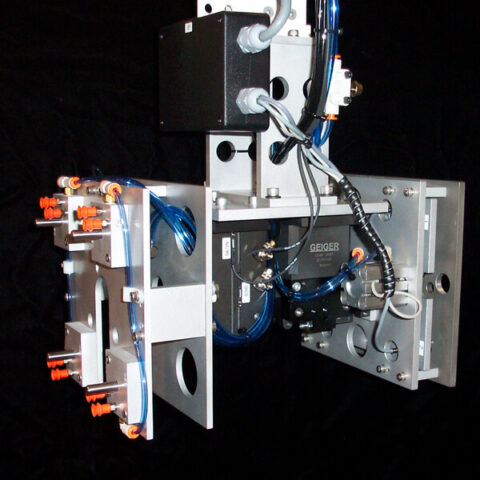

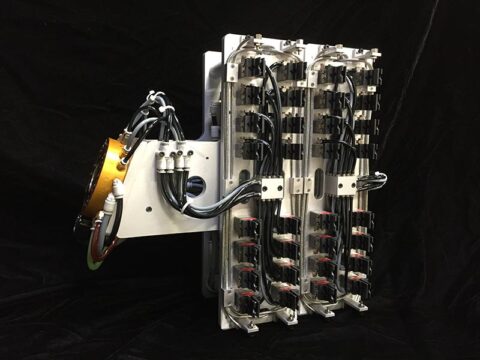

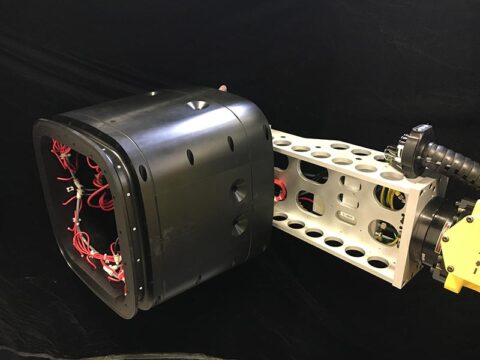

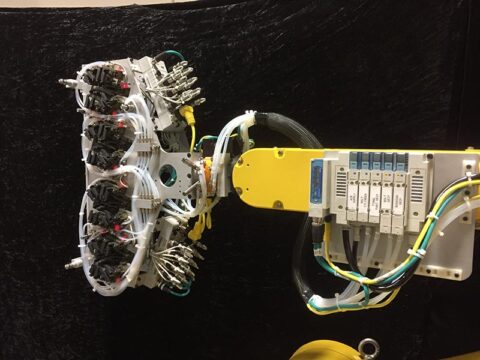

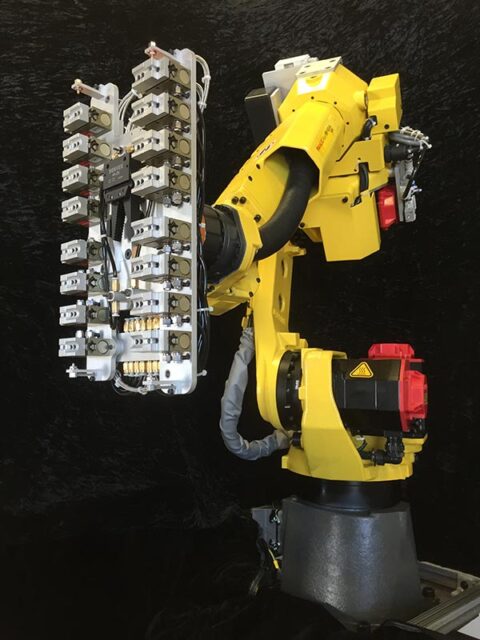

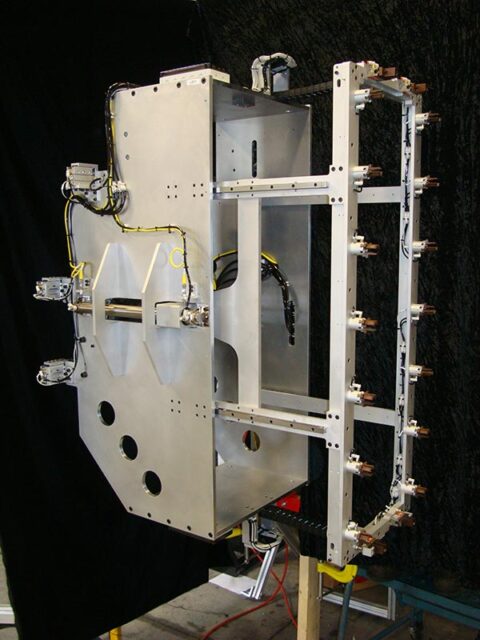

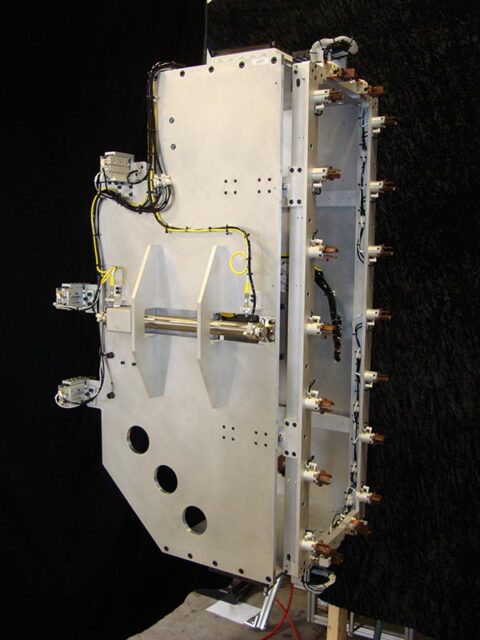

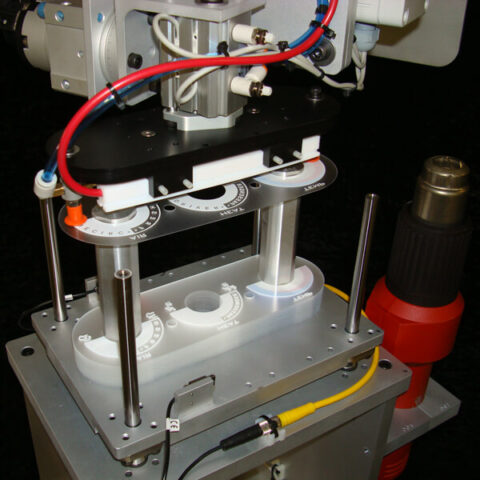

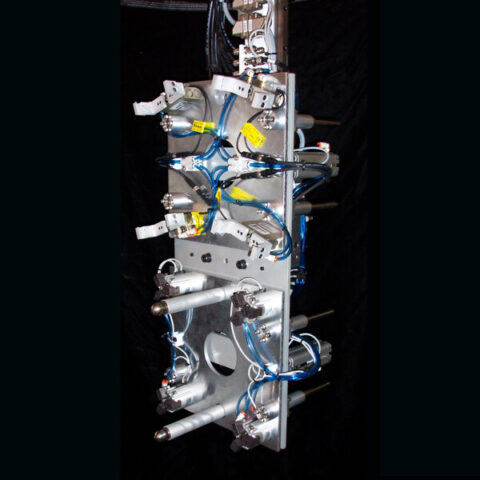

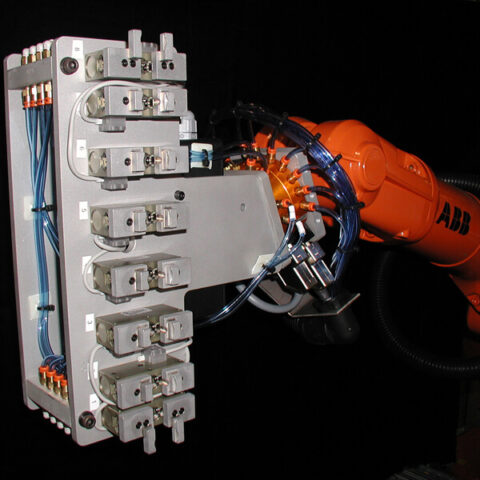

ATI QC20 high precision automatic tool changer with 8 Robohand 2-jaw parallel grippers and high tolerance docking

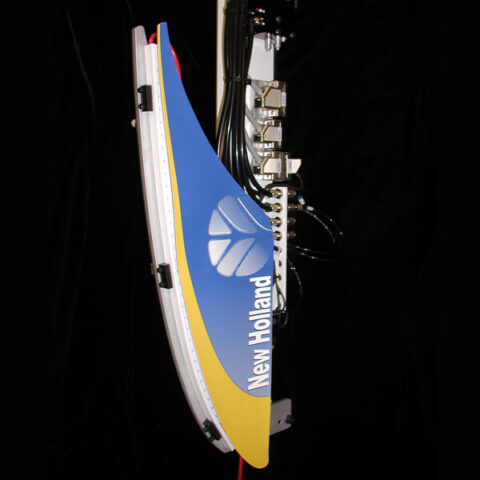

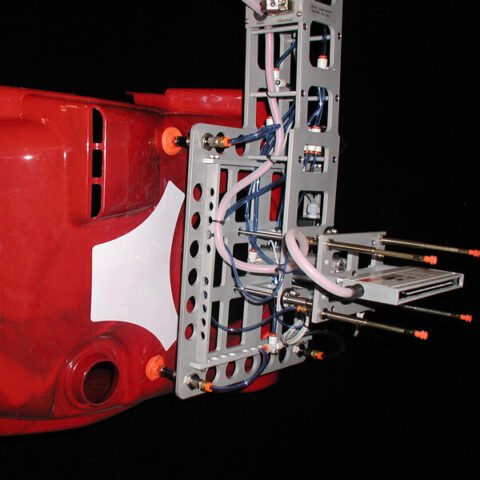

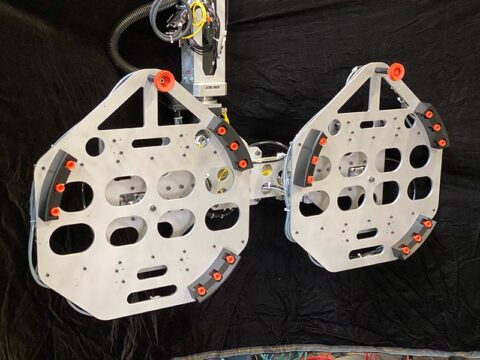

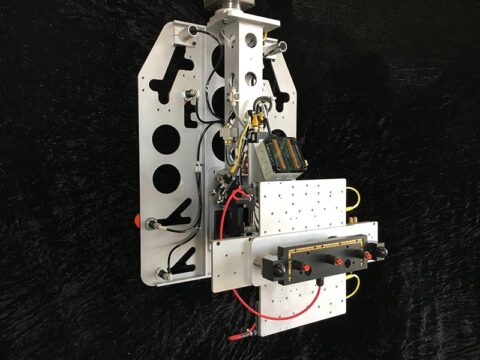

In-mold labeling (IML) custom end of arm tool with Simco static charging tetra bars

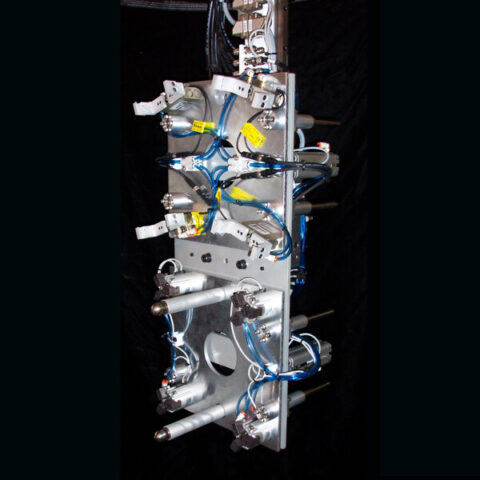

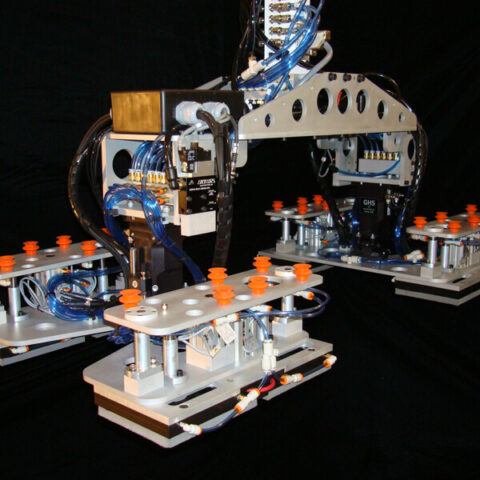

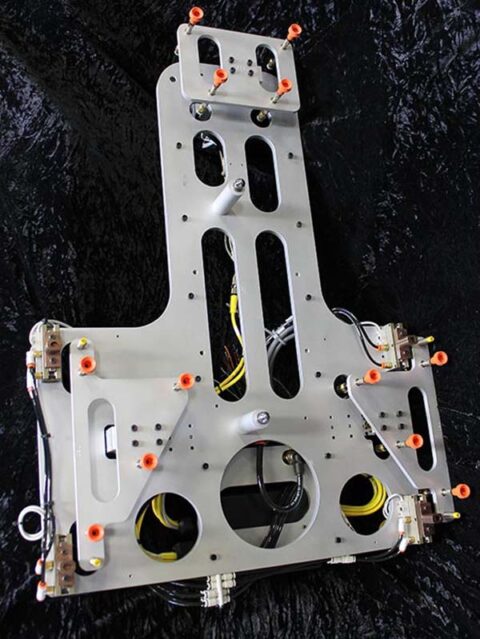

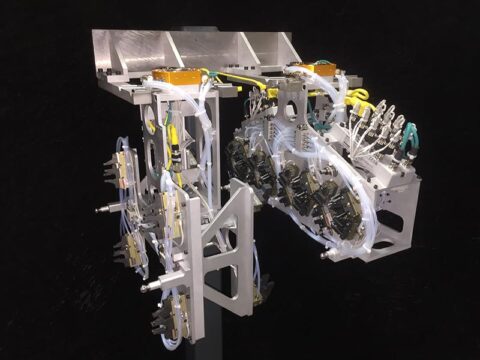

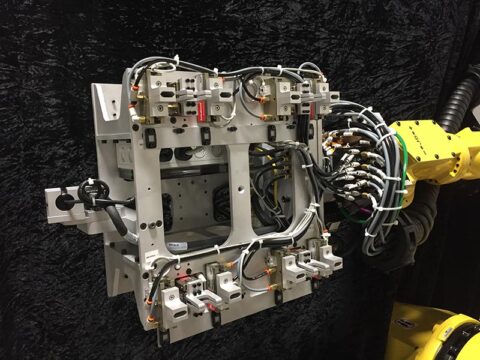

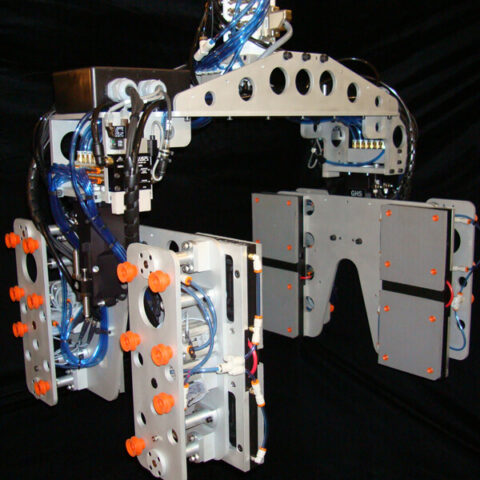

Dual function (same side pick & load) custom end of arm tool for automated part retrieval / insert loading of 4 cavities on movable half of the mold

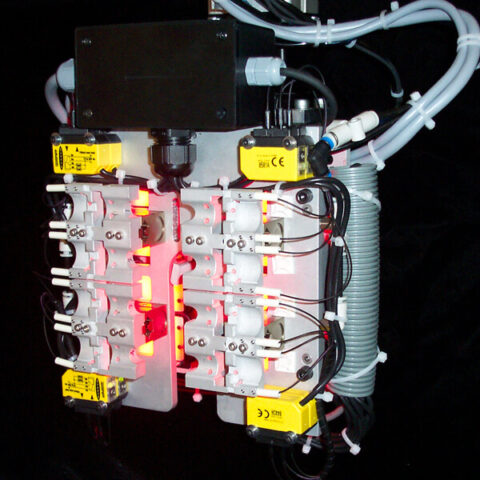

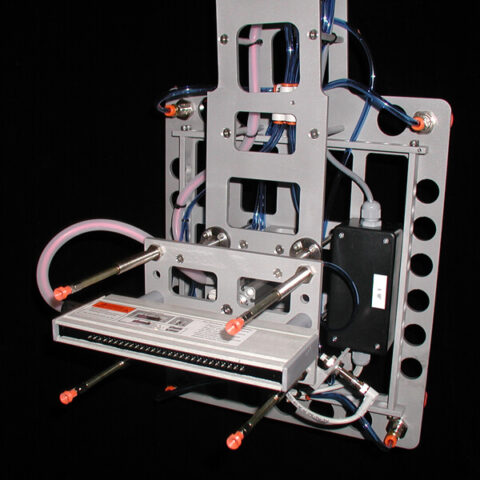

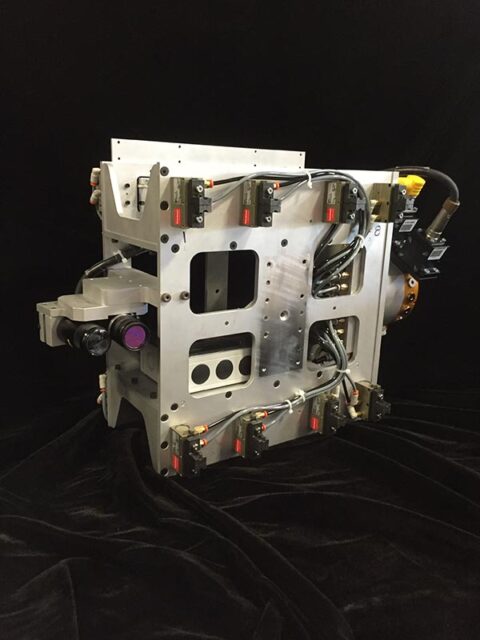

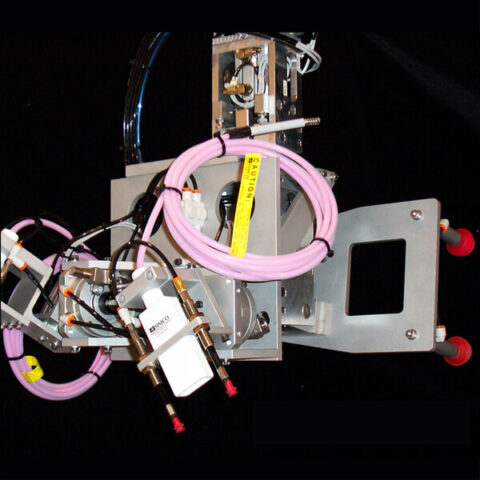

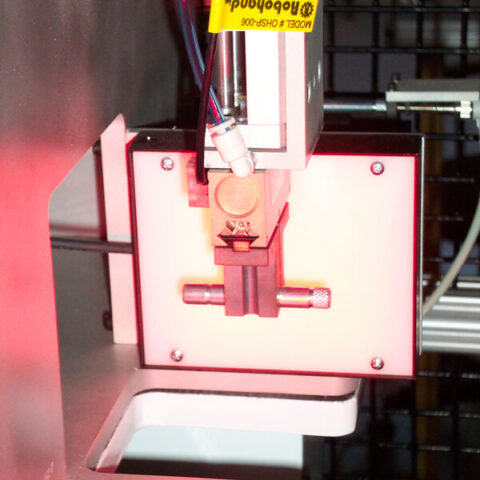

Backlit custom end of arm tool using a Cognex Camera for vision inspection and part confirmation

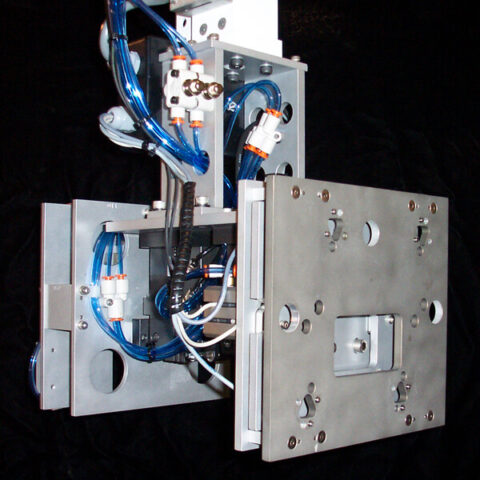

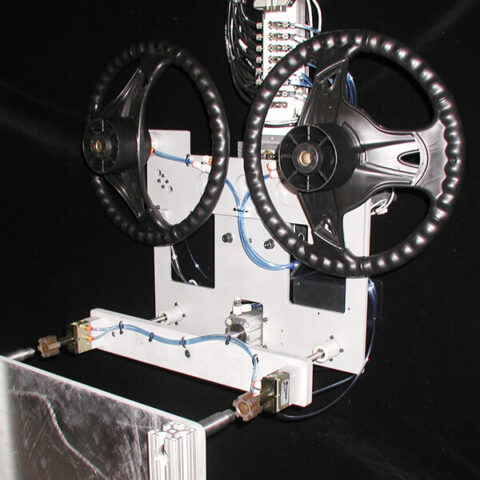

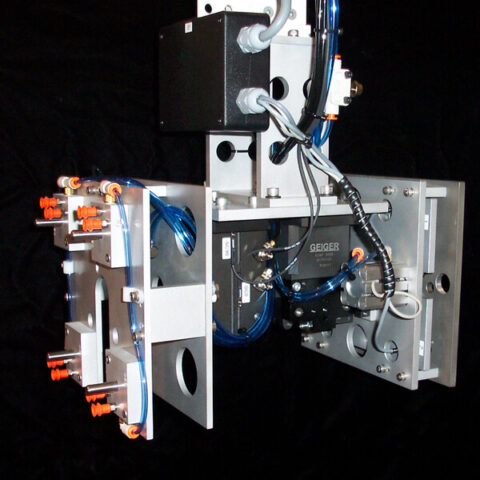

Dual function magnetic end of arm tool for picking up 4 metal inserts and loading into a horizontal plastic injection molding machine

Dual Function Insert Loading and part pick End of arm tooling

Direct charging, through resistive foam, for label placement and part picking automation on a 3-axis top entry robot

Direct charging custom end of arm tool with Simco spot chargers for in-mold decorating

Dual function end of arm tool for automated picking and placing on the moveable half of the mold

Dual function direct charging end of arm tool for automated label placement and part picking on a Fanuc Robotics 5-axis robot

Direct charging dual function custom end of arm tool for automated label placement and part picking on a Simco pinner bar, mounted on a 5-Axis beam robot

Custom end of arm tool for layer packing, with Edco B15 suction cups, mounted to level compensators affixed to a polycarbonate base plate

Dual Function Insert Loading and part pick End of arm tooling

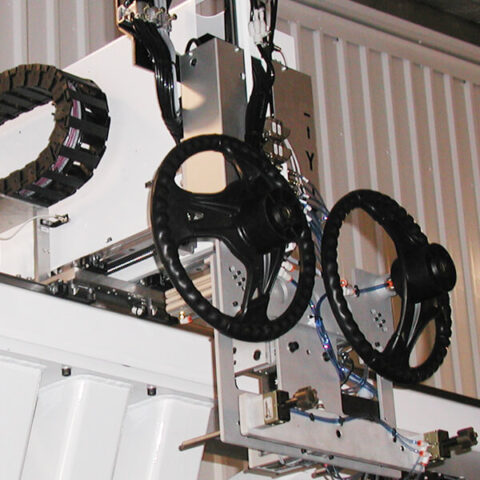

Custom In Mold Labeling End of Arm Tooling with Integrated motion and Docking.

16 Cavity Press to Press Transfer End of Arm Tooling

PVC Appliance Component Part retrieval End of arm tool for three axis top entry robot

Liquid Silicon Rubber Part extraction End Effector

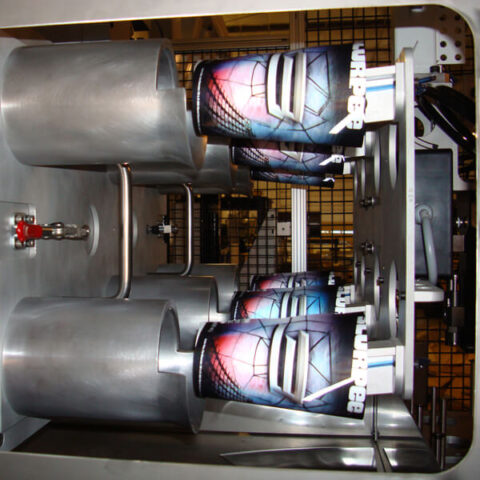

5 Gallon Custom In Mold Label Mandrel with Dual Rap Label End of arm tool utilizing Vacuum and Static Charging on a 6 axis Articulated Robot

Adjustable Dual Function In Mold Label and Part Picking Curb side Waste Container Lids

End of arm Tool Docking exchange station utilizing ATI Tool Changers with FANUC Six Axis Articulated Robot

Dual Function In Mold Label End Effector mounted on Three axis Top entry Servo Robot

Custom End of arm Tooling for Insert Loading and Part Picking on FANUC Six axis robot.

Press to press transfer First shot substrate and In Mold label from horizontal Injection molder to Blow molding press.

Dual Function End of Arm Tooling for Part retrieval and insert Loading on Six axis Articulated Robot

PVC Appliance Component Part extraction custom End of arm Tooling for WEMO three axis Top Entry Robot mounted on 750 Ton Horizontal Injection molding Machine

Vision Guided Dual Function Insert Loading and Part Picking End of Arm Tool Automotive Terminal Insertion, mounted on FANUC 6 Axis Articulated Robot.

Vision Guided Insert Loading End effector Dual function including Part Picking and ATI Tool Changer on FANUC M-710 Articulated Robot.

16 Cavity Part Picking end of arm Tool with Part confirmation on FANUC 6 Axis Articulated Robot including ATI Tool Changer

Dual Function Part Picking 2 cavity family mold End of Arm tool with integrated motion to extract parts from Stack Mold mounted on WEMO three axis Top entry Robot

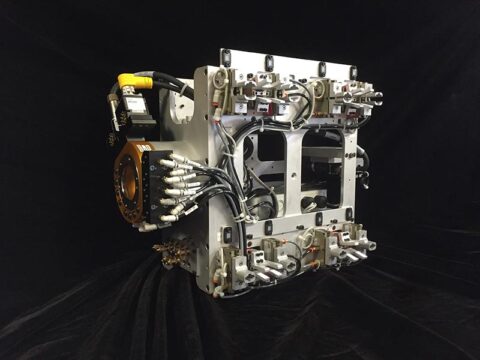

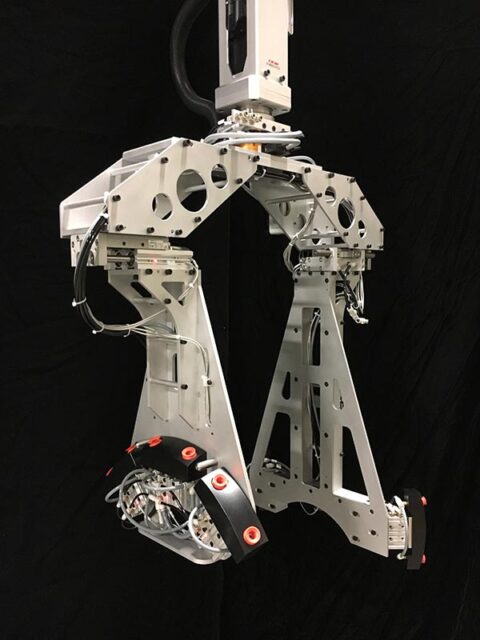

Custom End of arm Tool, Dual function to extract Automotive Oil Pan and re-load 18 Compression Limiters all on movable side of mold integrated on FANUC M900 260 L Articulated Robot

Custom End of arm Tool, Dual function to extract Automotive Oil Pan and re-load 18 Compression Limiters all on movable side of mold integrated on FANUC M900 260 L Articulated Robot

Part extraction End of Arm Tool for the Appliance Industry PVC 2 Cavity Side by Side employed on WEMO Three axis Top entry Robot.

IMD/IML Automation Solutions

Robotic Automation Systems is a leader and innovator of in-mold decorating (IMD) automation and in-mold labeling (IML) automation for the plastics industry, providing automation solutions that are custom engineered, built and fully integrated into your plastic injection molding application and process – from complete turnkey automation systems to specific robotic automation application needs and tooling.

With Simco static charging tetra bars for automated in-mold labeling application

Custom end of arm tool used in in-mold decorating (IMD) of cups for loading lenticular labels into a mock mold

Multi-label applicator (flat labels) for in-mold labeling / decorating, with Pinner bars and servo rotation motion built into the end of arm tool

High tolerance in-mold decorating (IMD) custom label nest with motion

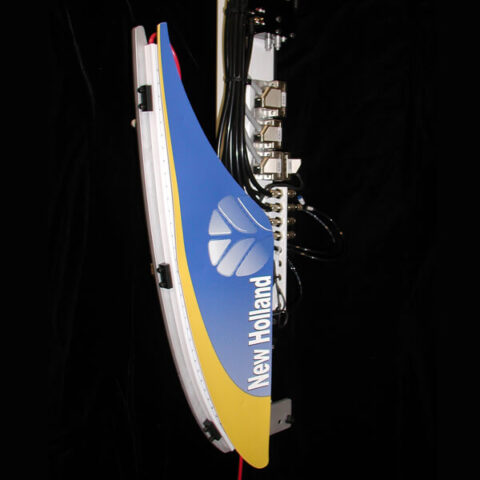

Custom turnkey automation cell for in-mold labeling of two labels on a single cavity of an ATV's front fender

Dual function direct charging custom end of arm tool for automated label placement and part picking, mounted on a 3-axis top entry robot

Custom end of arm tool with Simco spot chargers for in-mold decorating (IMD) / in-mold labeling (IML) automation

Insert Loading Automation Solutions

Robotic Automation Systems is a leader and innovator of insert loading automation for the plastics industry, providing insert loading automation solutions that are custom engineered, built, and fully integrated into your plastic injection molding application and process – from complete turnkey automation systems to specific robotic automation application needs and tooling.

Custom EOAT with retrieving parts and loading inserts on the same side of a 4 cavity mold

Vision inspection of steel shaft insert before it is handed off to the end of arm tool

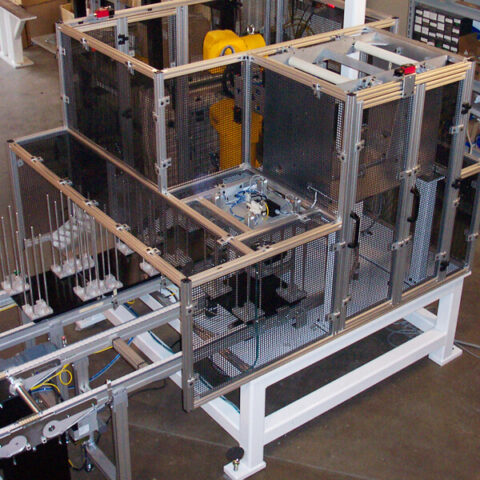

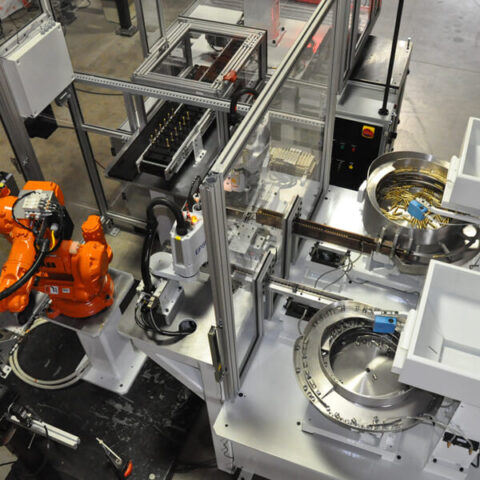

Full turnkey assembly cell, including insert loading and downstream automation of hot stamping and vision inspection

Plastic insert molding turnkey automation cell with custom end of arm tooling for loading 4 metal stampings, 0.001" clearance

Custom EOAT for loading inserts with magnets trapping and retaining the inserts on a 4 cavity dual c-axis rotation (rotating down to pick up parts on the flat and dropping parts onto a conveyor)

Vibratory fed inserts are orientated and pre-staged for an end of arm tool to pick up 2 inserts (parts picked with a Firestone inflatable air picker and inserts are reloaded into mold)

Custom dual function end of arm tool for loading two inserts and part retrieval, with inserts gripped by Robohand 2-Jaw parallel grippers, Firestone P025T Air Picker picking parts, and vacuum confirmation verification of retrieved parts

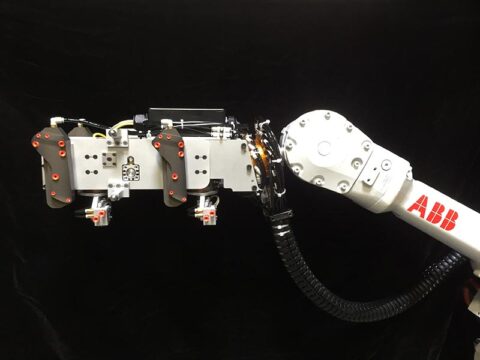

On an ABB Robotics IRB 1600 robot for transferring and loading a pre-molded plastic part for plastic insert molding

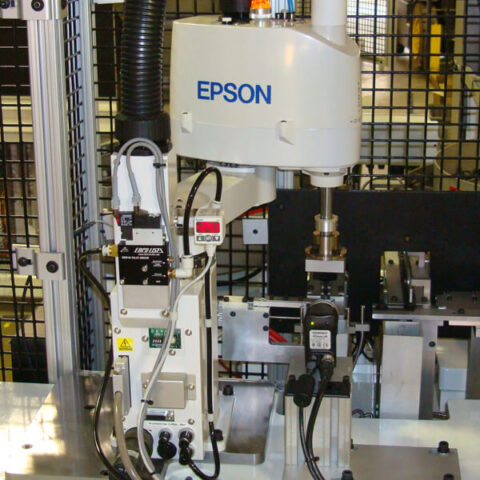

Two Epson SCARA Robots pre-staging a complement of 2 different inserts for picking by an ABB Robotics IRB 140 and loading into a vertical plastic injection molding machine

Assembly Automation Solutions

Robotic Automation Systems is a leader and innovator of robotic automation for the plastics industry, providing assembly automation solutions that are custom engineered, built and fully integrated into your plastic molding application and process – from complete turnkey assembly automation systems to specific robotic automation application needs and tooling.

Marrying two dis-similar parts using an Epson SCARA robot and Cognex vision inspection system to verify correct assembly

Employing a Staubli Robotics 6-axis robot for closing and stacking plastic injection molding parts (4x4 Stack) onto a flex link conveyor system with custom pallets

Including insert loading, cooling conveyor, downstream vision inspection, air gauging and packaging operations