3D Printing

Robotic Automation Systems 3D printing capabilities

RAS uses this technology to make robust parts specifically for end of arm tooling to maintain rigidity and accuracy with the ability to make parts that you cannot conventionally machine and also to help reduce the weight of the overall design. We have the ability to add heli-coils for added strength of threads as well as pause the prints to add thread inserts when needed.

We also make parts for customers, just contact us to send us a STL file and we can get you a quote and lead-time.

Robotic Automation Systems 3D printing capabilities

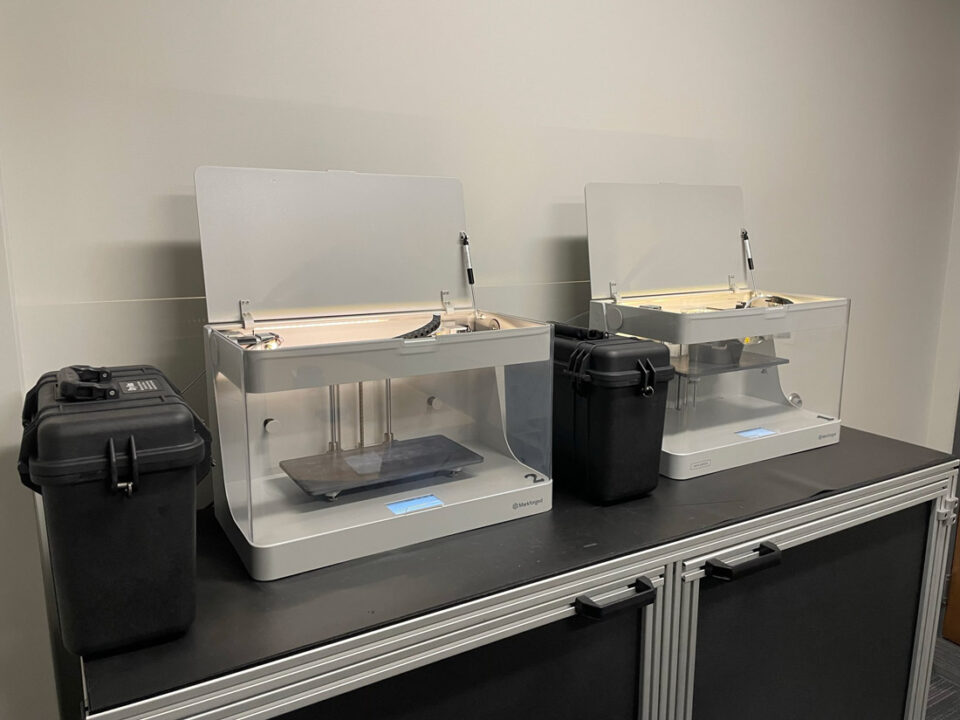

Two Onyx One Gen 2 3D printers with Fused Filament Fabrication

Z layer Resolution of 100 µm – 200 µm

Composite Base Filaments

Build size of 320mm wide x 132mm deep x 154mm tall

Material used is Onyx – Fused nylon and chopped carbon fibers

Parts have a great finish and strong and rigid.

Contact Robotic Automation Systems for Exceptional 3D Printing

3D printing processes can support nearly any industrial production project imaginable. From increasing prototype turnaround to experimenting with a large range of materials, 3D printing can make your product soar and should be an essential consideration for the production needs of your industry.

The experts at Robotic Automation Systems understand all the benefits of 3D printing and can point you in the right direction. Contact us to learn more about 3D printing!