6-Axis Robots | Articulated Robots

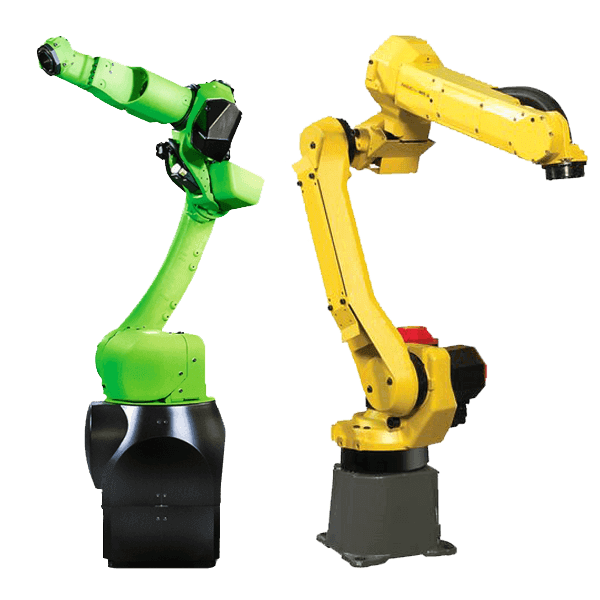

Industrial 6-Axis Articulated Robots

Robotic Automation Systems specializes in maximizing 6-Axis robots in your full turnkey automation over many industries, including horizontal and vertical injection molding, ensuring you always get the right robot for your applications.

6-Axis Articulated Robot Uses & Applications

6-axis articulated robots are employed for:

- Horizontal & Vertical Injection Molding

- Part picking and part handling automation

- In-mold decorating (IMD)/In-mold labeling (IML) automation

- Insert loading automation

- Overmolding (press to press transfer) automation

- Assembly cell automation

- Stacking and sorting automation

- Packaging and palletizing automation

- Inspection automation

6-Axis Robot Integration Solutions

Robotic Automation Systems proudly represents a broad range of high-quality, state-of-the-art 6-axis robots from the following manufacturers:

- ABB Robotics

- FANUC Robotics

In addition, our professional team has integrated plastic injection molding automation with 6-axis articulated-arm robots from the following robot manufacturers:

- Staubli Robotics

- KUKA Robotics

- Yaskawa Motoman Robotics

Contact Robotic Automation Systems Today

Discover more about Robotic Automation Systems and what our clients have to say about our expertise, service, and integrated solutions when it comes to finding solutions for your automation needs. Contact us to learn more!