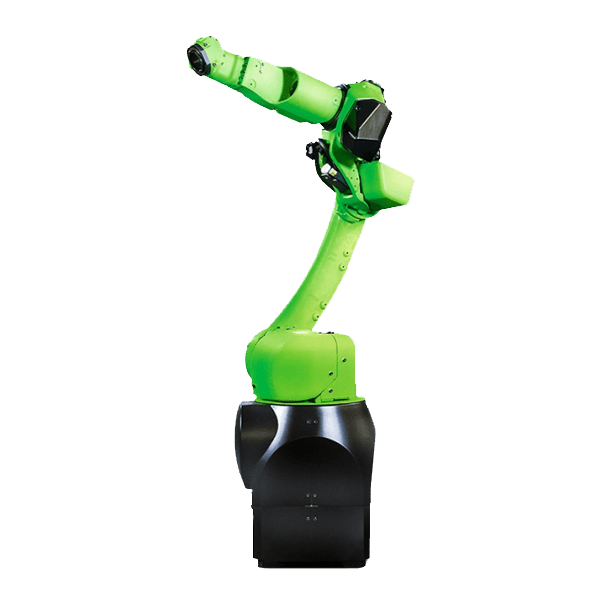

Robots

Industrial Robots Integrated

Our Robotic Automation Team Offer Integrated Solutions

Robotic Automation Systems utilizes a wide range of industrial robots to offer integrated solutions for your automation needs.

We engineer our turnkey automation systems to ensure you always get the right robot for your application.

We proudly represent a broad range of high-quality automation robots from several top-of-the-line manufacturers, including:

- WEMO Robots

- ABB Robotics

- Epson Robots

- FANUC Robotic

Industrial Robots

Robotic Automation Systems offers a wide range of robots for your industrial automation needs, including:

Contact Robotic Automation Systems To Start the Conversation for Your Applications.

Our line of advanced industrial robots offers streamlined solutions for all your production needs. The experts at Robotic Automation Systems understand all the benefits of robotic automation across many different industries and can point you in the right direction. Check out what our clients have to say about our expertise, service, and integrated solutions. Contact us to learn more about our state-of-the-art industrial robots!