Insert Loading Automation

Specializing in Insert Loading Automation

Robotic Automation Systems specializes in insert loading automation (upstream and downstream operations) for insert molding applications, on both horizontal and vertical plastic injection molding machines, from 15 to 6,000 tons.

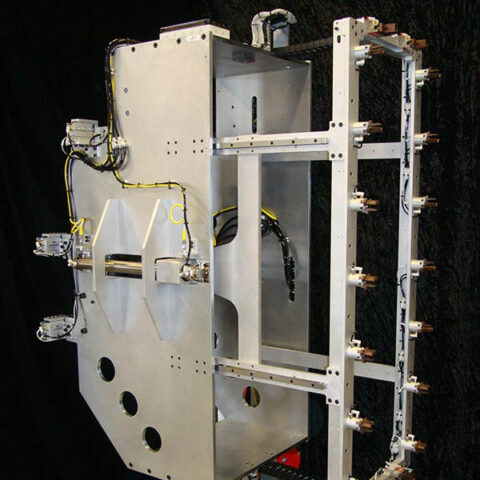

Insert Loading Automation

Turnkey automation cell for insert loading of four metal stampings, 0.001” clearance, for plastic injection molding

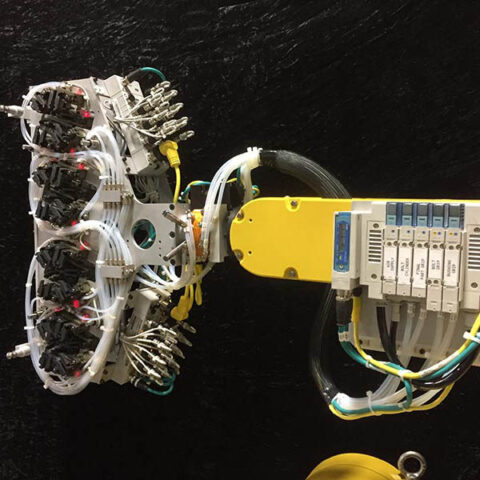

Insert Loading End of Arm Tool

Custom dual function end of arm tool for automated insert loading and part retrieval of two inserts for plastic injection molding, with inserts gripped by Robohand 2-jaw parallel grippers and Firestone P025T Air Picker, including verification of retrieved parts via vacuum confirmation

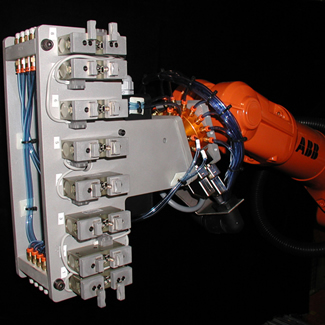

Automated Part Transfer & Loading

Custom end of arm tool (EOAT) on an ABB IRB 1600 robot, transferring and loading a pre-molded plastic part for plastic insert molding

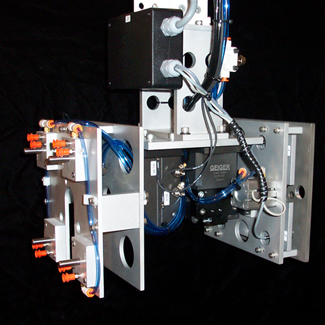

Insert Loading Automation EOAT

Custom end of arm tool for automatied insert loading in plastic injection molding process, using magnets to trap and retain inserts on a 4 cavity dual c-axis rotation (rotating down to pick up parts on a flat and dropping parts onto a conveyor)

Insert Loading Automation

- High Tolerance Insert Loading (0.0002 inch clearance)

- Docking (ensuring accurate alignment)

- Single and Multi-Cavity

- Cleanroom

Inserts

Ability to handle a broad range of insert types and materials, including, but not limited to:

- Stampings

- First Shot Molded Parts

- Threaded Inserts

- Shafts

Advantages

Use Robotic Automation Systems insert loading automation for:

- Reduced Cycle Time

- Consistent Cycles / Increased Part Quality

- Increased Productivity

- Reduced Scrap

- Mold Protection

Applications

Complete turnkey insert molding automation solutions for horizontal or vertical injection molding machines, including:

- Upstream Automation,

- Pre-staging Inserts (at cavity centers)

- Inspection / Verification

- Downstream Automation

- Part Retrieval

- Inspection / Verification

- Assembly

- Packaging

- Hot Stamping

- Pad Printing

- Other Auxiliary Operations

- Overmolding (Press to Press Transfer)

- End of Arm Tooling

- Docking

- Part Confirmation

Getting Started

Contact Robotic Automation Systems for more examples of our solutions for plastic insert molding automation, or to start a conversation about how we might help you with your insert loading automation needs.